Whether it is CNC or CNC milling, sometimes the workpiece coordinate system needs to be translated or offset as a whole when machining parts. This simplifies programming! How to operate? The following summary has three methods!

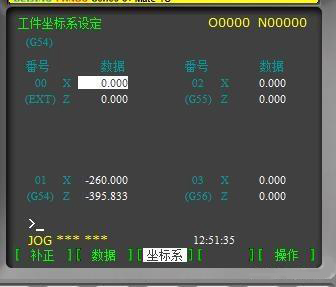

The first method utilizes six workpiece coordinate systems G54 to G59 provided by the system. For example, if you load six workpieces in one setup, the first workpiece is placed in the G54, and the second workpiece is offset from the first workpiece in the X or Z direction. Then you shift or shift in the G55. The amount can be entered in! Other analogy, after the knife is finished, select the corresponding G54~G59 in the program!

The second method directly uses the workpiece coordinate system offset command G50X-Z-. For example, the workpiece coordinate system wants to be offset by 10mm in the negative direction of Z, and is written as G52W-10 directly in the program.

The third method, probably the less common system parameter input method, G10P-X-Z-. If you want to shift the No. 1 knife to the positive direction of Z by 10mm, you only need to input G10P1W10 in the program; if it is No. 2, you only need to change P1 to P2!

The above three methods, choose a method that suits you, try to cut 10 slots on one axis, the reference procedure is as follows:

%O1; G52, M3S800, T0101, G0X52, Z-10, M98P02L10, G52W-60, G0X52, Z2, M5M30, %O2, G0Z-10, G01X40F0.1, G0X52, G52W-10, M99, %O3; G10 , M3S800, T0101, G0X52, #1=0, N1Z-10, G01X40F0.1, G0X52, #1=#1-10, G10P1W#1, IF[#1GE-60]GOTO1, G0X100, Z2, M5M30