数控走心车床指的是通过数控的程序来得到控制机床的目的,从而进行批量自动加工的操作,今日标准走心车床和普通的机床相比,拥有更好的适应性,在一些体积比较小、结构更加复杂的零件上都可以进行加工,而且拥有很高的精度,在生产方面拥有更好的效率,可以实现在同一台的走心床上进行很多道工序的加工,另外还具有劳动强度低,自动化程度高的优势。

Ordinary horizontal lathes are often used in the turning and threading of the inner and outer surfaces of the product. Usually, tools are used for drilling and reaming. It is a relatively high frequency used in China. Lathes accounted for 65% of all totals.

The difference between ordinary lathe and CNC walking lathe

1. When the ordinary lathe is threaded, the threaded rod of the trapezoidal thread is used for processing, and the processing is performed by using the polished rod for cutting, and the CNC lathe usually uses the ball screw when processing the thread. Processing method.

2. The position of the tool holder of the CNC walking lathe and the ordinary lathe is different. The position of the walking bed is basically on the left side of the operator, and the position of the ordinary lathe is usually on the right side of the operator. The difference is not good or bad, as long as it is more convenient for workers to operate.

3. The two lathes are different in the guide rail. The guide rails of the ordinary lathe are hard rails, and the walking core bed has the rails in addition to the hard rails.

4, the handle of the ordinary lathe is more, there are large, medium and small drag handles, and these are not in the heart bed, not only there is no small drag, the reduction of these accessories, shorten the operation process, let the workers It is more convenient when operating.

5. In terms of the equipment of the motor, there are also big differences between the two types of lathes. The ordinary motor of the ordinary lathe can use the ordinary motor, but if it is the eccentric bed, the variable frequency motor is usually used.

6, the caliper can achieve a greater range of automation operations, control of the spindle, feed, cooling pump, the traditional lathe use is manual control, the enamel can be fully automated operation, of course, can also be used manually Operational.

7, in addition to the ordinary lathe is not digital control operation, but go to the heart bed.

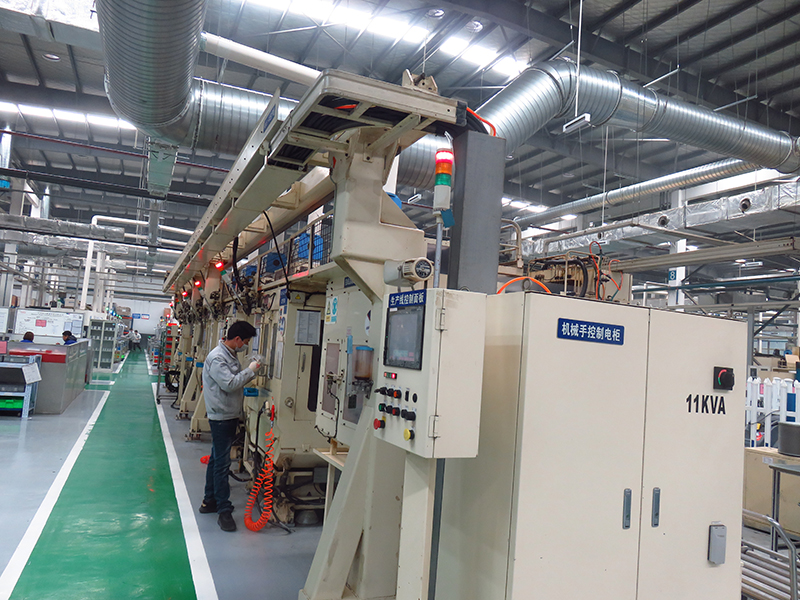

Advantages of CNC walking lathe

Walking the heart bed has better processing fineness, can get better product quality during processing, can move multiple coordinates, and can process some parts with more complicated shapes, if it is necessary When the machined parts are changed, only the NC program needs to be changed, and no other operation steps are required, which can save a lot of production preparation time. The ergonomics in productivity is very high, more than six times higher than ordinary machine tools.

CNC walking lathes do not have too many steps in operation, so the quality requirements of the operators are not particularly high, but the requirements for maintenance are higher, so it is necessary to hire professional equipment maintenance personnel, if you do not understand, It is not possible to handle it at will.