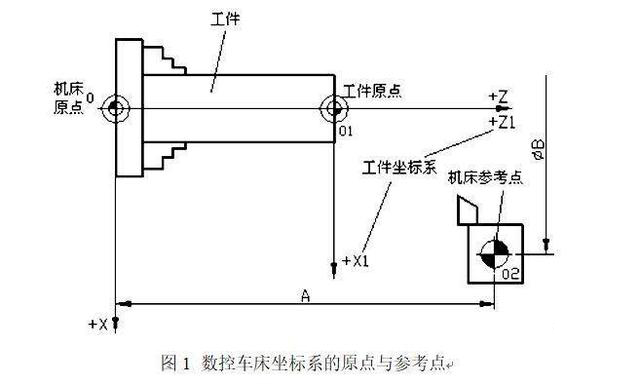

The origin of the CNC lathe coordinate system is generally defined at the intersection of the central axis of the chuck and the intermediate end face. As shown in Figure 1.

Figure 1 Origin and reference point of the CNC lathe coordinate system

When the CNC system is powered on, it does not know where the zero point of the machine coordinate system is. In order to correctly establish the machine coordinate system when the machine is working, a machine reference point is usually set in the movement range of each coordinate axis, as shown in Figure 1. After the CNC lathe is started, it is necessary to make a motorized or manual reference point (called “zero return” operation) to establish the machine coordinate system.

Programming coordinate system

The programmed coordinate system is an artificially set coordinate system. It is easy to calculate by analyzing the size of the pattern, and it is easy to program. Generally, the requirements of the processing reference on the pattern are first found, and the programming origin is determined under the requirements of the process and precision. The programmer selects a known point on the workpiece pattern as the origin (also called the program origin) and creates a new coordinate system called the programmed coordinate system.

Workpiece coordinate system

The programmed coordinate system is only established on the drawing. The CNC lathe system does not know the coordinate system set by the programmer. Then the operator moves the origin of the programmed coordinate system to the CNC lathe by means of tool setting, etc., at this time on the CNC lathe. The established coordinate system is called the workpiece coordinate system, and its origin is generally selected at the intersection of the axis and the right end face, the left end face or other positions of the workpiece. The Z axis of the workpiece coordinate system generally coincides with the spindle axis, and the workpiece coordinate system is always valid once it is established. Until replaced by a new workpiece coordinate system. As shown in Figure 1.

The purpose of the tool is to determine the position of the program origin in the machine coordinate system, convert the origin of the programmed coordinate system into a known point of the machine coordinate system and become the origin of the workpiece coordinate system. This point is called the tool point and the tool point. It can be coincident with the program origin, and it can be used at any convenient location.