The use of CNC machine tools in production and processing is more and more extensive, which makes the CNC machine tools gradually become grounded, no longer the same high-end equipment. The combination of data processing, control circuitry and servo system in CNC machine tools is called CNC system. CNC machine tools can be used normally, relying on the basis of the CNC system. For the CNC system, the following is a detailed introduction.

1. According to the trajectory that can be controlled

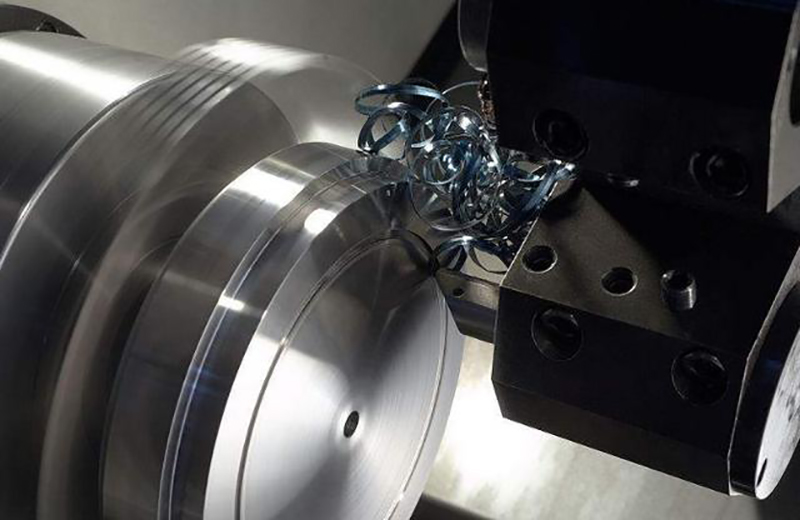

The system that can control the motion trajectory is suitable for machine tools for machining curves and curved surfaces such as CNC lathes, CNC milling machines, machining centers, etc., which are mostly used in modern CNC machine tools.

(1) Point control:

Only accurate positioning movement of the tool from one point to another relative to the workpiece can be achieved. No control is required for the trajectory, and no other processing is performed during the movement.

(2) Continuous control:

This control, also known as contour control, can control several feed axes to coordinate motion at the same time, allowing the workpiece to move relative to the tool at a specified trajectory and speed, and to perform continuous machining during motion.

2. according to the servo system control method

(1) Open loop control system:

Usually, a stepping motor is used as the driving element, and the input feed command is in the form of a pulse. Without the position measuring device, the signal flow is also unidirectional from the numerical control device to the feed system, so the system stability is good. Without position feedback, the accuracy is not high relative to closed-loop systems, depending on the performance and accuracy of the servo drive system and mechanical drive mechanism. The general servo drive component is a power stepper motor.

The advantages of this system are mainly simple structure, stable operation, convenient debugging, simple maintenance, low price and so on. However, its shortcomings are mainly that the accuracy and speed are not high. It can be widely used when the driving torque is not large, and is generally used in economical CNC machine tools in production.

(2) Semi-closed loop control system:

Such a system is taken from the drive or the lead screw and the sampling rotation angle is detected, and the actual position of the moving part is not directly detected. Semi-closed loops do not include or include a small number of mechanical transmission links for stable control performance. However, due to the pitch error of the lead screw and the gear gap, it is difficult to eliminate the motion error, so the accuracy is poor compared with the closed loop, which is better than the open loop.

(3) Closed loop control system:

The full-closed CNC system directly detects the actual position of the moving parts, which eliminates errors and gaps in the entire drive and transmission, and has high position control accuracy. This type of system is often used in ultra-precision lathes, superfinishing machines and boring and milling machines that require high precision.